Abstract : a study of fluidized bed spray granulator of the minimum fluidization velocity, particle steady fluidization and its control method, spray granulation mechanism and sudden instability phenomenon. Pointed out that the minimum fluidization velocity of the experimental value is much larger than the theoretical values, but can pass on the bed pressure drop of monitoring, to achieve a smooth flow of operation control. Particles to reunion way grow up, and sudden instability of wet is the main failure form of the fluidized granulation. Discusses a variety of process parameters on the granulation and sudden instability effects, the results help to guide the actual production.

Key words: fluidized bed spray granulation; change; instability; mechanism of

Fluidized bed spray granulation process mixing, granulation and drying process of the 3 integrated in one device, with simple process, compact equipment, low energy consumption, good environmental protection performance, suitable for heat-sensitive materials and particles has the advantages of easy solution, is a more advanced granulation method and equipment, in the industry increasingly wide range of applications.

In this paper the pharmaceutical industry in the FL-3C type fluidized bed spray granulator for research object, corn starch as material, by analyzing some experimental phenomena and mechanism analysis, studied the equipment powder particle fluidized condition and its control method, granulating mechanism, operation parameters on the stability operation effect.

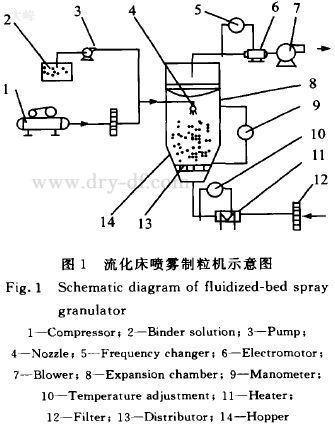

1 experimental apparatus

Using a modified FL-3C type fluidized bed spray granulator as experimental device and its working principle, as shown in figure 1. Air from the blower 7 into the granulator, is absorbed by the air filter 12 filter, then heated by a heater 11, a distribution plate 13 at the bottom of the container into the hopper 14 and the expansion chamber 8, the powder fluidizing and drying, and finally, after the bag type filter discharge. Fluidized air flow through the fan motor variable frequency speed regulation. Adhesive liquid by infusion pump 3 suction, then located in the expansion chamber 8 upper atomizing nozzle 4 ejected downwards.

Using the above experiment device, with corn starch as raw material, gelatin for spray adhesive, using different operating parameters ( adhesive liquid spray rate, fluidized air inlet temperature, atomizing air pressure, liquid adhesive adhesive liquid concentration, adding amount and spraying time etc.), carried out a large number of fluidized bed spray granulation experiment. Following on the observed during the experiment phenomena and its mechanism was discussed.

2 powder stable fluidized condition research

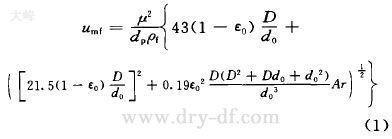

The fluidized bed spray granulation, ensure the equipment within the powder in a fluidized state is stable, achieve granulation necessary condition. Generally, powder particles minimum fluidization velocity can be a reference for design of fluidized bed on the formula, the conical fluidized bed type (1 ), can be used for calculating minimum fluidization velocity umf.

When the device size is too small, unable to realize the fluidization gas; gas is too large particle is adsorbed to the bag wall, also cannot realize pelletization. In the pharmaceutical industry, granulation powder to the initial particle size smaller, generally in the range of a few microns to several tens of micrometers. In the experiment using corn starch size in 2um ~ 3um. But if the actual size of powder substituted for (1 ) calculating minimum fluidization velocity, found the obtained theoretical minimum fluidization velocity and the experimental values are very different, the measured minimum fluidization velocity is far greater than theoretical value.

Through a lot of experiments and observations, the big difference is the powder by air and sticky surface force formed a loose agglomerates.

With the decrease of the particle diameter, particle surface area is inversely proportional to the particle diameter and increased significantly. And particles of gravity compared, powder adhesion surface force on particle fluidized behavior increases gradually. Therefore, on the surface of ultrafine particles, because of the viscous force, under the natural state is usually to agglomerate form, rather than in an isolated primary particles form.

However, granulation powder to the initial particle size are generally in the range of several to tens of micrometers range, its sticky surface force and gravity is still very weak, so in the natural state is still primary particle form. However, fluidization fine powder due to airflow and sticky surface force, movement can form a large loose agglomerates, stop the flow of the agglomerates, disintegrated, and thus it is difficult to directly observe. In addition, the fluidization process of two-phase flow phenomenon, also can increase the actual minimum fluidization velocity.

In this paper, using corn starch granules, if according to the measured minimum fluidization velocity and type ( 1) inverse of initial fluidization of the equivalent diameter, can be obtained, in the fluidization in the formation of the agglomerated particles particle diameter in hundreds of micrometers.

3 smooth flow of control method research

Effects of powder particle fluidized state of many factors, when the fluidized bed spray granulator size structure is determined, the different powder particle size, density, moisture content, gas velocity, particle aggregation, two-phase flow is influenced by the fluidized state. As a result of fluidized powder agglomeration phenomenon, the experiment at the actual minimum fluidization velocity than the theoretical value is much greater, so in the actual production process, it is difficult to use the theory and method to determine the fluidized bed spray granulation of initial fluidization

Gas velocity and suitable fluidized gas velocity.

根据流化床理论,在固定床阶段,床层压降随气体流速的上升而增大。到流化床阶段,床层保持在一个基本恒定的床层压降水平。在固定床和流化床的交接处,床层压降将有一突变。对锥