We are in process optimization, diagnosis, measurement and improvement of assets to provide a unique service. We offer our customers high technology system, in-depth practical application of knowledge to the overall differences in the formation of competitive advantage, reflected in the high-speed production, products closer to the technical indicators, reduce costs, improve efficiency and so on. The production of such products, according to today’s environmental provisions, requirements for product type, powder type, the moisture content, or toxic features to make a more complex process design.

To meet the needs of customers and local governments,Da Feng have been successfully developed and provided a lot of processing equipment.

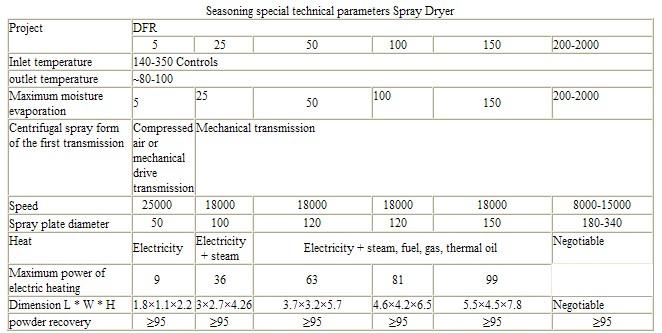

Spray Dryer is our dedicated group of spices for the oil, sugar, fat, salt and other high moisture easily drying heat sensitive raw materials designed for a specific product. It solves the material easy to soften at high temperature melting, which to ensure continuity of production. We summarize 20 years of experience in design and manufacture of spray dryer, the same industry at home and abroad to collect the same type of product strengths, through sophisticated technical calculation and repeated numerous experiments experiment, developed Seasoning special spray dryer group, and promote the use of some well-known flavoring plants, received a very satisfactory result.

|

|

|

|

|

|

|

|

调味品专用喷雾干燥机组是我们针对含油,含糖,含脂肪,含盐等较高的易吸湿的热敏性物料干燥而设计的一款专用产品. 它解决了物料在高温下易软化熔融,从而保证了生产的连续性.我们总结了20年来设计制造喷雾干燥机的经验,收集了国内外同行业同类型产品的长处,经过精密反复的工艺计算和无数次的实验试验,研究开发出了调味品专用喷雾干燥机组,并推广到一些知名调味品厂使用,收到了极为满意的效果。

Flow of cooling air delivery system

As the special seasoning, using conventional drying system under the barrel cyclone feed directly to income method, the resulting products are often a piece of the lump material. I plant for its handsome first developed a special anti-caking system, has been in chemical and biological products, oligosaccharides, fruit and vegetable powder, spices and other areas of special spray dryer is widely used to prove their good effect.

The system consists of: refrigeration dehumidifiers, HEPA filter, air delivery flow of cooling pipe, electric heater, cyclone and so on. process: the material down into the cyclone from the cyclone, cyclone separator between the export to not use any valves, the pressure to rely on the formation of cyclone winds sent the material flow of the cooling pipe into the outside world except After the wet cold air through the HEPA filter after the fan back into the flow of the cooling pipe with suction cyclone material into contact cooling, and then into the small cyclone clean packing room, the materials are separated into material warehouse packing, exhaust gas into the drying tower to tower tangential sweep. the process to conventional equipment in addition to the original rotary valve under the cyclone, the use of advanced cyclone, so that the material will not stick valve. Dehumidification of air flow through the material cooled, the powder surface water removal, elimination of powder material within the thermal power to lower the temperature, more material to retain the active ingredient, to ensure that packaging materials do not agglomerate at room temperature

spray drying technology

Spray drying developed in Europe since the 20th century as the drying skim milk has now become the food industry for the manufacture of the grinding powder of the most successful food drying technology. Its characteristics are, the liquid raw material powder directly into products, to a large number of continuous treatment, without grinding process can be obtained directly uniform particle size, solubility and dispersion of a very excellent products.

Abroad, mainly spices seasoning factories mostly in the use of "MD spray drying device" is a project developed by Da Feng production, the spray dryer will be too concentrated stock solution directly in a spray form into the dry tower, the formation of steam fog-like droplets in the air in contact with the heated moment of evaporation, together with the hot air exhaust port from the oven, leaving the material that is dried into a powder drop bottom. This spray dryer for the milk and other food processing plants and pharmaceutical manufacturers widely use, and marketing overseas.

Da Feng of the two-stage company development and production of drying device "multi-stage spray dryer system" for the loss of non-pipeline structure, the lower part of the exhaust chamber through the hopper part of the large particle powder will selectively delay the time to obtain a secondary drying stranded effect, the exhaust chamber of the vertical height of nozzle spray dryer has always been 50% or less, which makes the traditional models can not handle the powder spray dryer --- the pool is strong, lack of liquidity powder material Here again the formation of a single-stage drying effect, so it is easy to achieve drying. The dryer the monomer structure, mostly small-scale research institutes and manufacturing enterprises selected for the production of small quantities of different varieties. Its advantages: Set site is small, the price is low; can be short-term automatic washing; char, rather than for the non-dual air heating; can be required due to the characteristics of different materials to change the import and export of hot air temperature and adjust the diameter of the pipe; by cooling Cyclone Dust Collector manufactured goods and many other cool features high gain market evaluation. Riken Vitamin Company, such as Chiba and factories have been selected for this spray dryer of many varieties of small batch production.

In addition, the Da Feng of development and production company also made a DFRP good market assessment, the main features are: can not store to achieve continuous drying. SUS304 materials used, structural safety and good health, for food material handling. Good thermal efficiency, product quality is high, does not produce char, rather than, color. Low prices, the recent U.S. housing company pills have adopted it to continuous processing sauce powder.

Da Feng production of spray drying company developed device, the use of the clean-type external mixing nozzle, there is no need to worry about sticker plug the nozzle, continuous spray operation can be realized for a long time, while manufactured by changing the diameter of the edge different nozzles to spray volume.

Research and development of spray drying experimental machine used in the manufacture of a small amount of fine powder after the test product, the expanded scale of production can get the same test machine with fine particles. The sprayer has established the actual state of spray material confirmed the glass window, and experimental data confirmed by the screen image can also be printed.

Particles of spray-dried products, the advantages for the drying time is short, and low temperature, products, color and flavor deterioration is also less. At the same time the material directly from the liquid obtained by simplifying the process of powder products, save energy, and effort requirements. And compact device itself, the required site area is also small, equipment costs and transportation costs are lower.

The characteristics and present situation of tobacco flavoring and seafood flavoring were reviewed in the present paper, And a perspective in the research development and industrial process of maillard reaction is given.

It has been widely applied in the condiment production and showed great superiorities.

调味料喷雾干燥机具有高效、节能、操作方便、无污染等优点,已在调味品生产中广泛应用,是替代常规喷雾干燥机的优选设备。

|

|

|